Pressing Cider Apples

This is an introduction paragraph....

PRESSING CIDER APPLES

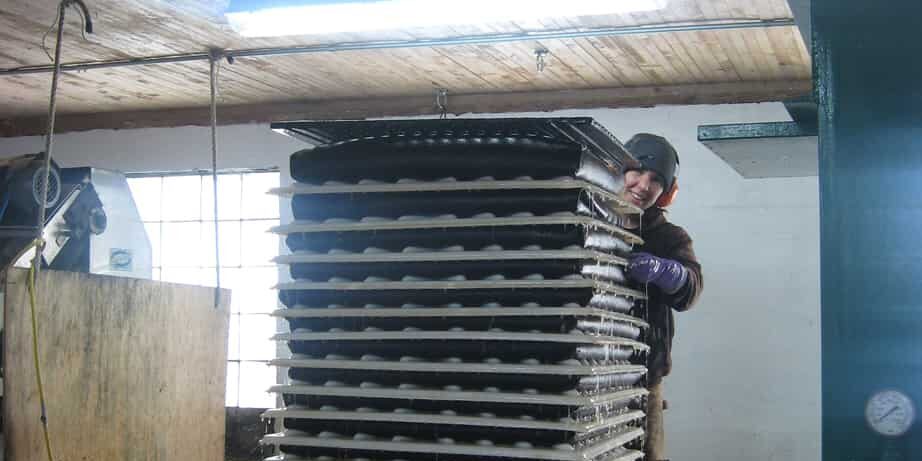

Each layer of pommace is equal to roughly two and a half bushels of apples. There are 13 layers in a single press. A press can yield anywhere from 80 to 110 gallons of juice depending on the variety of apples. It takes us about 2 hours per press from start to finish plus 2 hours of set up in the beginning and 4 hours of break down at the end.